Welcome Weihai Global Chemiacl Machinery MFG Co., Ltd.!

Service Hotline

0631-5766828

Advanced Search:

CONTACT USContact Us

HOTLINE:0631-5766828

(7x24)

Mob:13061173293

Fax:0631-5766838

Tel:0631-5766938

Address:No.2, South No.1 Road, YangTing Village, HuanCui District

Hydrothermal Synthes

Name:山东100ml Homogeneous Reactor

Details

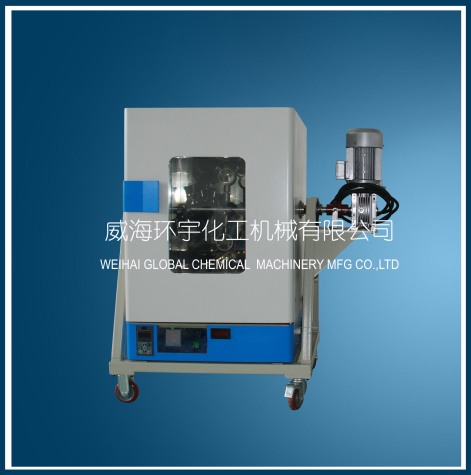

Homogeneous Reactor (Special for Pressure Heating Stirring Reaction)Introduction of Homogeneous Reactor

1. Use

Homogeneous stirred reactor can be used to test the reaction conditions of the same component medium under different conditions or the reaction conditions of different components medium under the same conditions. This product uses electric heating blast drying box as heating constant temperature device, and drives the mixing shaft in the box and the micro reactor installed on the mixing shaft to rotate through the motor reducer to achieve the purpose of mixing reaction.

2. Characteristics

Homogeneous stirred reactor generally consists of four parts: box, rotating system, heating system and control system. The box body is made of stainless steel (304/316), and the rotating system consists of motor, reducer and rotating bracket. The control system mainly controls the temperature and speed in the box. Homogeneous reactor is often used in many hydrothermal synthesis reactor to test the reaction condition of the same component medium under different environment or for the reaction condition experiment of different component medium under the same condition. Because of the rotation of the support, the medium in the hydrothermal reactor is fully stirred, so the reaction speed is fast and the reaction is thorough, which is better than the simple constant temperature effect. There is a fixed position on the stirring rod in the tank (according to the size of the reactor), which can fix 6 sets, 8 sets, 10 sets and 12 sets of miniature reactor at the same time, and can be customized according to the needs of users. Specific dimensions are subject to customer requirements.

3. Applicable object

The constant temperature digital display of the homogeneous stirred reactor shows that the user can set the temperature according to the reaction experiment. The mixing system is equipped with a variable speed device, and the speed can be adjusted arbitrarily (frequency conversion speed regulation) from 0 to 300 revolutions. It is easy to operate and use. It is an ideal equipment for hydrothermal reaction experiments in laboratories of universities, pharmaceutical and chemical industries and scientific research institutions.

4. Hydrothermal Synthetic Reactor (Pressure Volume Bomb)

Hydrothermal synthesis reactor (also known as digestion tank, digestion tank, high pressure digestion tank, hydrothermal kettle, pressure bomb) is used for sample pretreatment of chemical analysis methods such as gas phase, liquid phase, plasma mass spectrometry (ICP-MS), atomic absorption spectrometry and atomic fluorescence, and for food, geology, metallurgy, environmental protection, commodity inspection, chemical industry, nuclear analysis. Industrial and other systems, digestion of heavy metals such as Pb, Cu, Zn, Fe, Ga, Rb, Hg in agricultural residues, food, rare earth, aquatic products and other organic materials, as well as nanomaterials, compound synthesis, crystal growth and so on. When the pressure of high-pressure reactor is lower than 6MPa, gasket seal is used, metal double-wire seal is used when the pressure is higher than 6MPa, static seal and strong magnetic stirring are used for stirring, and various stirring slurries can be prepared. The explosion-proof heater can be made by electric heating with special requirements.

Specification: 25ml, 50ml, 100ml, 150ml, 200ml, 500ml, 1000ml

Material: 1Cr18NI9Ti (optional special material) can also be customized according to user needs.

Pressure: -0.1-30 MPa (special requirements are discussed separately)

Temperature: <260 degrees (special requirements are also discussed)

Lining: Polytetrafluoroethylene (PTFE), strong acid and alkali resistance and other organic solvents

Method of operation:

When the reactant system is corrosive, it should be placed in the tetrafluoro bushing to ensure that the reactor body is not corroded. The hydrothermal synthesis reactor is placed in the heater and heated to the required reaction temperature (less than the prescribed safe operating temperature) at the prescribed heating rate. When the reaction is finished, the cooling rate should also be strictly operated in accordance with the prescribed cooling rate, so as to facilitate the safety and the service life of the reactor. After confirming that the intra-abdominal temperature is lower than the boiling point of the solvent, the cover of the reactor can be opened for subsequent operation.

Every time the hydrothermal synthesis reactor is used, it should be cleaned in time to avoid rust.

Careful attention should be paid to cleaning the sealing parts of the kettle body and the kettle cover line, and the damage of the kettle should be strictly prevented.

Pressure Bomb, Pressure Vessel,Hydrothermal Synthesis Reactor

Address:Yujiakuang, Yangting Town, Huancui District, Weihai City, Shandong Province

Address:Yujiakuang, Yangting Town, Huancui District, Weihai City, Shandong Province  Tel:0631-5766828

Tel:0631-5766828 E-Mail:huanyu01@wh-huanyu.com Record No:

E-Mail:huanyu01@wh-huanyu.com Record No: About Us

About Us Product

Product Contact Us

Contact Us scan code

scan code